The automotive body-in-white (BIW) market plays a pivotal role in the vehicle manufacturing process, focusing on the production of the vehicle’s body shell before any moving parts are installed. This segment represents the vehicle’s foundational structure, including the frame and exterior panels, which are critical for the safety, durability, and integrity of the final vehicle. As the automotive industry rapidly evolves, several trends, including advancements in materials and manufacturing processes, are shaping the BIW market. One of the most transformative forces driving these changes is Artificial Intelligence (AI), which is enhancing various aspects of the BIW process, from design to production.

Key Market Insights

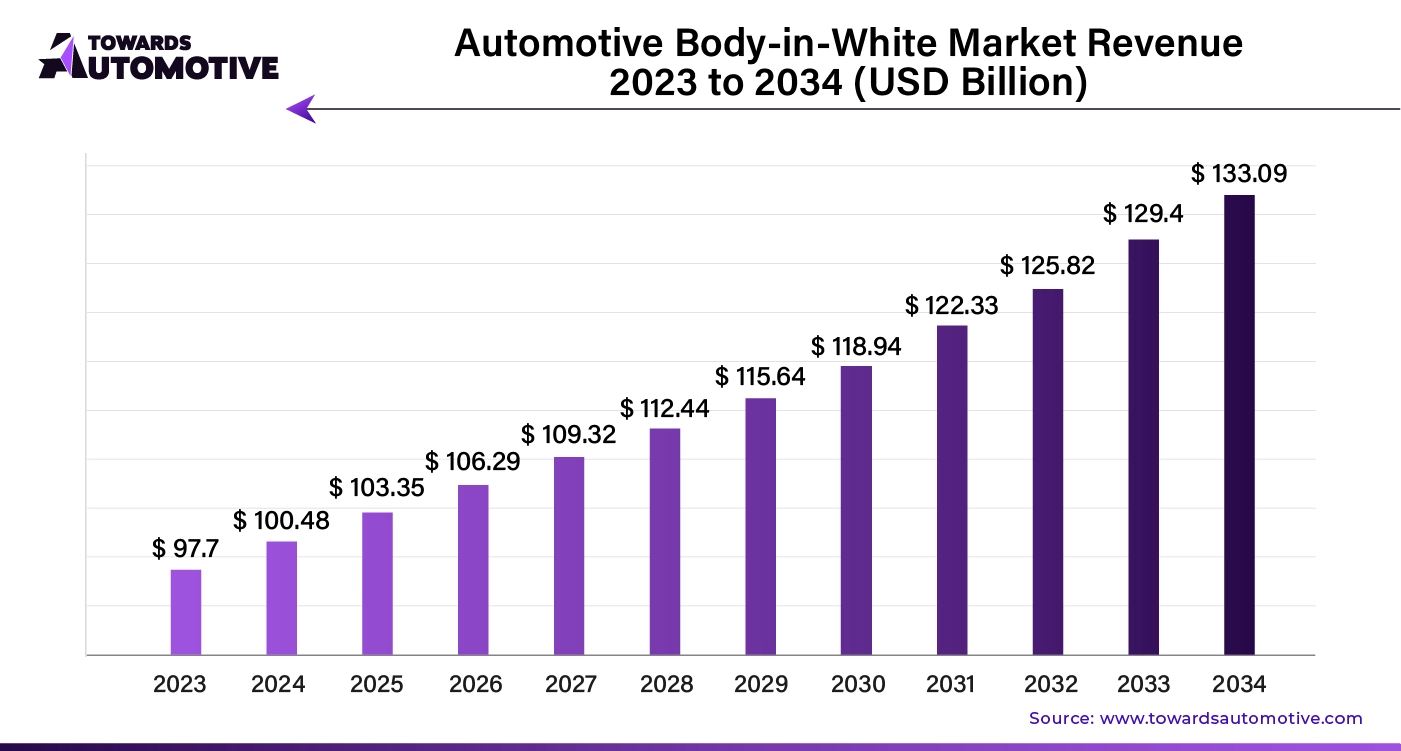

The global automotive body-in-white market is currently valued at USD 100.48 billion in 2024 and is projected to grow to USD 133.09 billion by 2034. This represents a steady expansion at a compound annual growth rate (CAGR) of 2.85% over the next decade.

Get All the Details in Our Solution – Download Brochure @ https://www.towardsautomotive.com/download-brochure/1477

- Asia Pacific Dominates the Market: The Asia Pacific region currently leads the market, driven by a strong presence of vehicle manufacturers and growing automotive production.

- Europe Expected to Grow with the Highest CAGR: Europe is expected to experience the highest growth rate during the forecast period, as technological advancements and the increasing adoption of electric vehicles (EVs) continue to shape the market landscape.

- Material Trends: Steel remains the dominant material used in BIW, offering strength, cost-effectiveness, and versatility. However, there is a growing trend towards lightweight materials like aluminum and composites, driven by the rising demand for fuel-efficient vehicles.

- Passenger Vehicles Lead the Market: The passenger vehicle segment holds the largest market share, benefiting from the continued demand for personal transportation.

- Electric-Powered Vehicles Show Strong Growth: The electric-powered segment is expected to experience the fastest growth, driven by the global shift towards sustainable and energy-efficient transportation.

Technological Advancements in Automotive BIW Production

The automotive BIW market is undergoing significant transformation, largely due to advancements in materials and manufacturing technologies. The shift towards lighter, stronger materials and the integration of more advanced safety features are driving the demand for innovative BIW solutions that cater to the evolving needs of the automotive industry.

One of the most notable technological trends in the BIW market is the rise of automation and robotics. Automation in manufacturing processes, powered by AI, is helping companies streamline their production lines, improve efficiency, and reduce costs. AI algorithms optimize robotic movements, enabling faster and more accurate assembly of vehicle bodies. This has led to higher production rates and greater precision in critical operations such as welding.

Additionally, AI is significantly improving the design phase of BIW. By simulating various stress and impact scenarios, AI can help engineers develop body structures that are both robust and lightweight. These AI-powered simulations improve the safety, fuel efficiency, and overall performance of vehicles by ensuring that the BIW can withstand various challenges while being as light as possible.

AI in Quality Control and Predictive Maintenance

AI also plays a crucial role in enhancing the quality control processes within the BIW production line. AI-driven vision systems and machine learning algorithms are increasingly used to identify defects during production. These systems can detect even the smallest deviations from specifications, ensuring that each BIW meets rigorous quality standards. As a result, manufacturers can minimize defects, reduce costly reworks, and deliver a higher-quality finished product.

Furthermore, predictive maintenance powered by AI is transforming how manufacturers manage machinery and equipment in BIW production. By analyzing data from machines and sensors, AI systems can predict potential failures before they occur. This proactive approach reduces downtime, minimizes maintenance costs, and ensures a continuous flow in the production process.

Managing Complex Supply Chains with AI

The automotive industry’s supply chain is incredibly complex, with manufacturers needing to manage the timely delivery of raw materials, parts, and components to meet production schedules. AI plays a crucial role in optimizing this supply chain by analyzing data on material availability, demand, and logistics. With AI-driven tools, companies can streamline inventory management, reduce delays, and ensure that the necessary materials are available when needed.

Toyota’s Launch of Generative AI

In June 2023, Toyota made waves in the automotive industry with the launch of generative artificial intelligence (AI) at its Toyota Research Institute (TRI). This technology is expected to revolutionize the vehicle design process by assisting designers in developing components more efficiently. By harnessing the power of AI, Toyota aims to create innovative vehicle components that can enhance both performance and design.

Invest in Our Premium Strategic Solution @ https://www.towardsautomotive.com/price/1477

You can place an order or ask any questions, please feel free to contact us at sales@towardsautomotive.com

Explore the comprehensive statistics and insights on automotive industry data and its associated segmentation: Get a Subscription

For Latest Update Follow Us: https://www.linkedin.com/company/towards-automotive