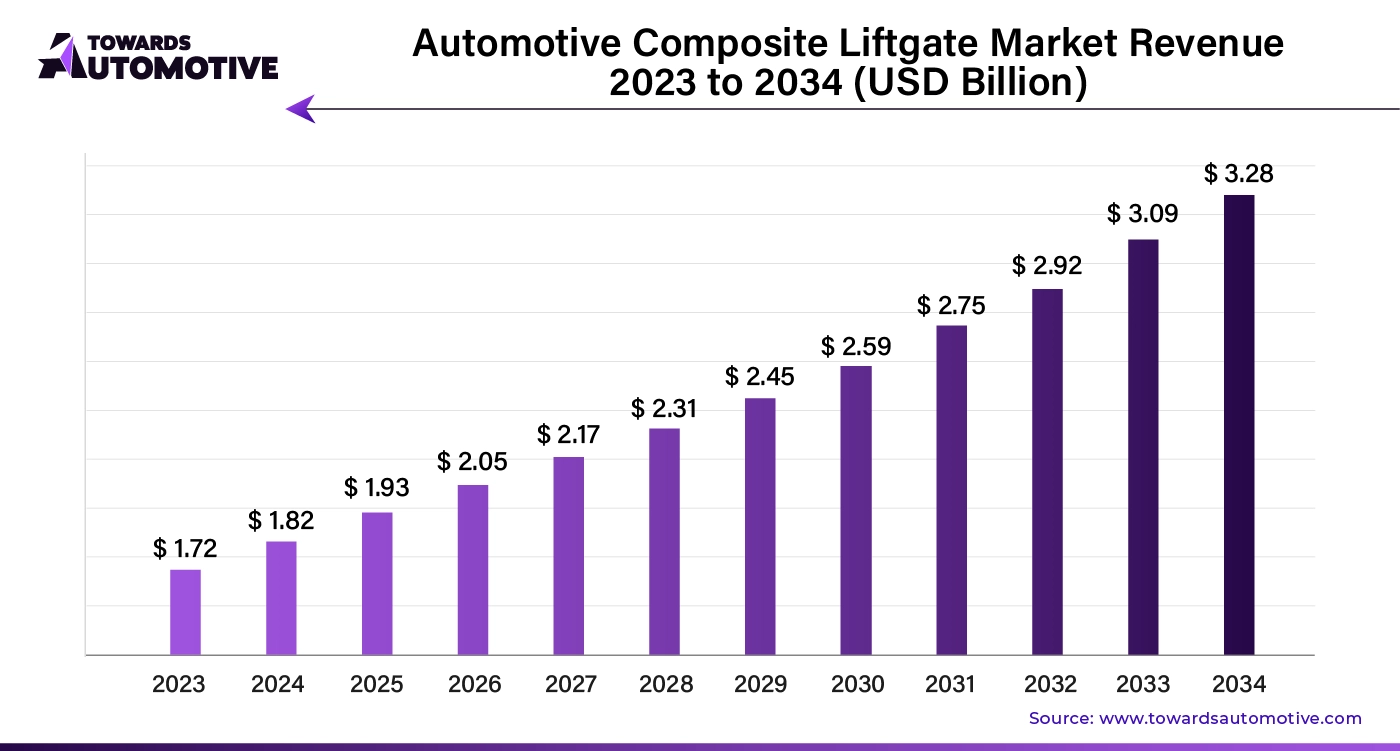

In recent years, the automotive industry has witnessed significant advancements in vehicle design, especially in the integration of composite materials. One area where these innovations are most evident is in the design and manufacturing of liftgates. Composite materials offer numerous advantages, from reducing vehicle weight to improving fuel efficiency, making them an attractive choice for both conventional and power liftgates. The global automotive composite liftgate market was valued at USD 1.72 billion in 2023 and is expected to reach approximately USD 3.28 billion by 2034, growing at a compound annual growth rate (CAGR) of 6.04% from 2024 to 2034. Here, we delve into the current trends in liftgate types, manufacturing processes, and vehicle segments, and explore how composite materials are shaping the future of the automotive sector.

Get All the Details in Our Solution – Download Brochure @ https://www.towardsautomotive.com/download-brochure/1476

Liftgate Type Insights

The conventional liftgate segment was the market leader in 2023. Conventional liftgates, which have been a staple in automotive design for years, are popular due to their established manufacturing processes and the familiarity they offer to both consumers and manufacturers. These liftgates provide a balanced mix of cost and functionality, making them suitable for a wide range of vehicle types. Notably, they are commonly found in larger vehicles like SUVs and crossovers, where the impact of weight reduction is particularly significant. The integration of composite materials into these conventional liftgates enables manufacturers to achieve lighter weight, which is crucial for improving fuel efficiency and meeting stricter fuel economy standards.

On the other hand, the power liftgate segment is projected to experience the fastest growth during the forecast period. The increasing consumer demand for convenience and high-end features has made power liftgates a desirable option, particularly in luxury and higher-end vehicles. These automated liftgates offer enhanced ease of use, especially for families or individuals who frequently carry large items. The growing use of composite materials in power liftgates is helping to reduce overall vehicle weight, which contributes to better fuel efficiency and longer electric vehicle range. As automakers continue to develop lightweight yet durable components, power liftgates are expected to become an even more integral feature in modern vehicles.

Manufacturing Process Insights

In terms of manufacturing, compression molding led the market in 2023. Known for its efficiency and ability to produce large, complex parts with consistent quality, compression molding is particularly well-suited for automotive applications. The process allows for the rapid production of composite liftgates, which is essential to meet the high demand from the automotive sector. Additionally, compression molding supports the use of a wide variety of composite materials, enhancing the strength and durability of the liftgates. The method’s cost-effectiveness, coupled with its ability to minimize waste, makes it an attractive option for manufacturers looking to keep operational costs low while meeting sustainability goals.

While compression molding remains the dominant process, resin transfer molding (RTM) is expected to grow at the highest compound annual growth rate (CAGR) throughout the forecast period. RTM offers several advantages, including superior control over material properties, which enables the production of lightweight yet strong components. This process involves injecting resin into a closed mold containing dry reinforcement materials, allowing for precise material distribution and minimal waste. RTM’s flexibility in producing intricate designs and complex geometries makes it ideal for creating aesthetically pleasing and aerodynamically efficient liftgates. As the automotive industry shifts toward lightweight materials, particularly for electric and hybrid vehicles, RTM’s ability to produce large, robust components positions it as a key player in the market.

Vehicle Type Insights

The SUV segment dominated the market in 2023, a trend expected to continue for the foreseeable future. The rising consumer preference for SUVs, which are valued for their spaciousness and comfort, has driven the demand for larger liftgates. These vehicles benefit greatly from the lightweight properties of composite materials, which help enhance fuel efficiency and overall performance. Additionally, the rugged durability requirements of SUVs align well with the strength and resilience provided by composite materials, making them a preferred choice for manufacturers.

According to industry projections, the unit sales of SUVs are expected to reach 26,310,000 vehicles by 2028. This indicates a sustained dominance of the SUV segment in the coming years. Furthermore, the hatchback and sedan segment is expected to generate significant revenue as well. Hatchbacks and sedans often feature more compact designs, allowing for creative use of space and innovative features. The use of composites enables manufacturers to create complex shapes and structures, offering both aesthetic appeal and functionality.

Industry Developments

Key industry developments highlight the growing importance of composites in automotive design. In July 2022, Woodbridge, a supplier of molded foam, expanded its operations with a new manufacturing facility in Tianjin, China. The 58,000-square-foot facility is dedicated to producing molded foam, a type of composite material, which will support the company’s customers in the region.

In October 2021, IDI Composites International showcased the versatility of composite materials with the selection of their Fortium material for Hyundai’s 2022 Santa Cruz Sport Adventure Vehicle (SAV). Fortium, a composite material with 40-65% glass fiber reinforcement, offers high strength and impact resistance, making it an ideal choice for automotive applications.

Invest in Our Premium Strategic Solution @ https://www.towardsautomotive.com/price/1476

You can place an order or ask any questions, please feel free to contact us at sales@towardsautomotive.com

Explore the comprehensive statistics and insights on automotive industry data and its associated segmentation: Get a Subscription

For Latest Update Follow Us: https://www.linkedin.com/company/towards-automotive