The integration of Artificial Intelligence (AI) in the electric excavators market is revolutionizing construction and excavation processes, driving advancements in operational efficiency, safety, and productivity. As the construction industry embraces smarter and more sustainable technologies, AI is emerging as a game-changer for electric excavators, offering a host of benefits that enhance the performance and capabilities of these machines.

Optimizing Operational Efficiency

AI plays a pivotal role in automating excavation tasks. Through machine learning algorithms, electric excavators can optimize excavation patterns and manage load handling more effectively. AI-powered systems can predict and adjust the excavation process in real time, enabling more precise and efficient operations. This level of automation reduces the need for manual intervention, freeing up operators to focus on higher-level tasks and increasing overall productivity.

One of the most significant advantages of AI is its ability to optimize the operation of electric excavators in real-time. By analyzing operational data from various sensors embedded in the excavator, AI ensures that the machine is performing at its peak efficiency. For electric excavators, this includes optimizing battery usage and minimizing energy consumption, which is crucial for extending the operational life of the machinery and reducing overall energy costs.

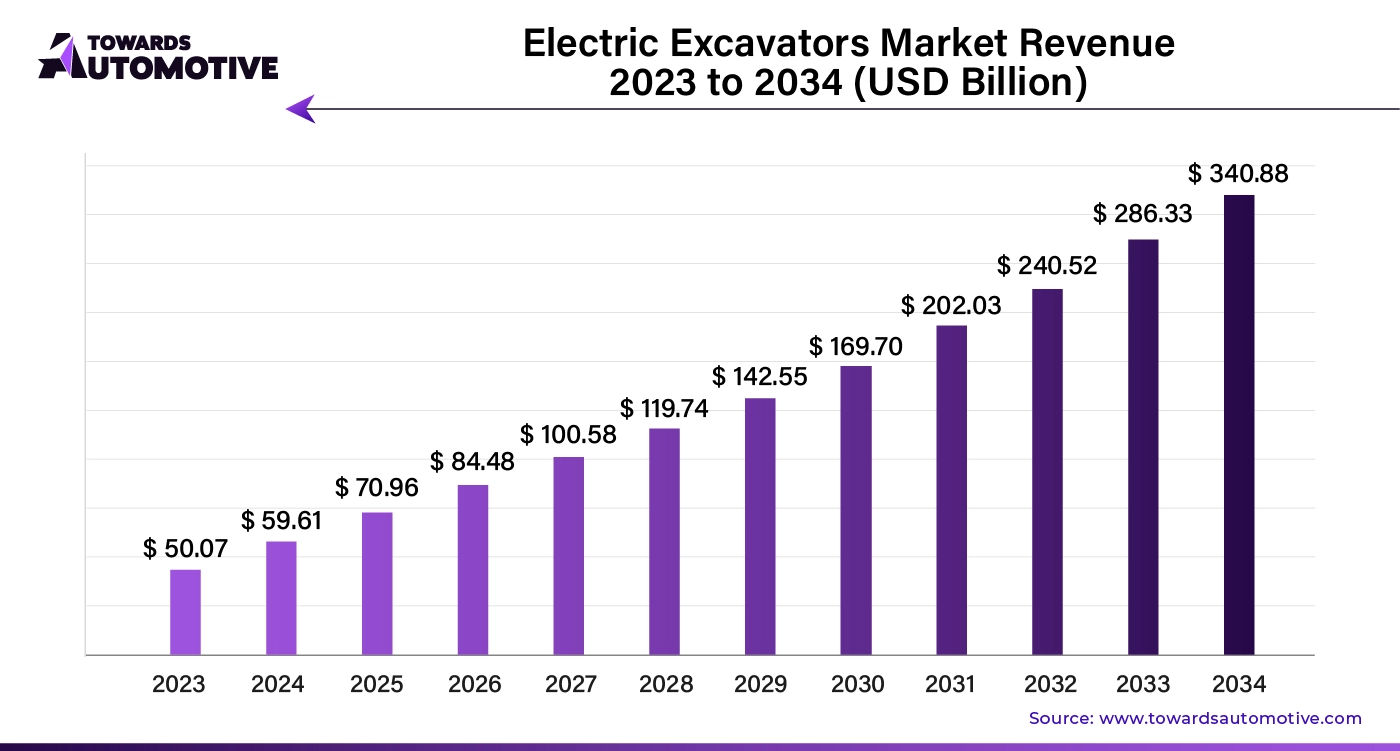

The global electric excavators market, valued at USD 59.61 billion in 2024, is expected to grow to USD 340.88 billion by 2034. This remarkable growth is driven by technological advancements like AI, along with increasing demand for electric and sustainable machinery. The market is projected to expand at a compound annual growth rate (CAGR) of 19.05% from 2024 to 2034, highlighting the rising adoption of electric excavators in the construction sector.

Get All the Details in Our Solution – Download Brochure @ https://www.towardsautomotive.com/download-brochure/1472

Predictive Maintenance and Enhanced Reliability

One of the key features AI brings to electric excavators is predictive maintenance. Equipped with a network of sensors, electric excavators continuously gather data on wear and tear, hydraulic pressure, temperature, and other critical factors. AI algorithms process this data to predict potential equipment failures before they occur. By analyzing patterns in the data, AI can forecast when components may need maintenance or replacement, allowing for proactive action.

This predictive approach helps minimize costly repairs and reduce unplanned downtime, which is essential for maintaining project timelines and avoiding disruptions. Moreover, by identifying potential issues early, AI extends the lifespan of electric excavators, making them more reliable and cost-effective in the long run.

Enhancing Safety Through AI-Driven Features

AI technologies are also making construction sites safer by enhancing hazard detection and collision avoidance systems. Electric excavators are equipped with a variety of sensors and cameras that feed data to AI algorithms, which analyze the environment in real-time. These systems can detect obstacles, such as other machinery or personnel, and automatically adjust the machine’s movements to avoid accidents.

The ability of AI to process complex data in real-time ensures that these safety systems are responsive and effective, preventing accidents before they happen. This not only improves the safety of operators but also protects nearby personnel, making construction sites more secure.

Real-Time Data Analytics and Remote Monitoring

AI also plays a crucial role in improving site management and work processes through data analytics. By collecting and analyzing data from sensors, AI algorithms provide actionable insights into how to optimize operations. This could include recommendations for improving excavation efficiency, optimizing fuel consumption, or adjusting operational parameters to adapt to changing site conditions.

Additionally, AI enables remote monitoring and control of electric excavators. Operators can oversee machine performance and adjust settings from a distance, ensuring that equipment is running smoothly without needing to be physically present on-site. This remote control capability is especially useful for managing fleets of excavators, allowing for better coordination and enhanced operational efficiency.

Hyundai’s AI-Enabled Electric Excavator

In a major step forward for the industry, Hyundai launched an AI-enabled electric excavator in April 2024. This advanced machine is designed to enhance construction activities by leveraging AI technologies to streamline operations and improve overall productivity. Hyundai’s AI-based electric excavator is equipped with a range of AI-driven features that optimize battery usage, predict maintenance needs, and enhance safety on construction sites.

The introduction of AI-enabled electric excavators like Hyundai’s marks a significant milestone in the construction industry’s shift towards smarter, more sustainable machinery. As the demand for electric and autonomous machines continues to grow, AI will play an increasingly critical role in shaping the future of the construction sector.

Invest in Our Premium Strategic Solution @ https://www.towardsautomotive.com/price/1472

You can place an order or ask any questions, please feel free to contact us at sales@towardsautomotive.com

Explore the comprehensive statistics and insights on automotive industry data and its associated segmentation: Get a Subscription

For Latest Update Follow Us: https://www.linkedin.com/company/towards-automotive